Can Excel Be Used to Implement AIAG-VDA Process FMEA (PFMEA) Methodology?

If you currently manufacture one component products with a simple process and use an Excel template for PFMEAs, it is going to take more time and effort to create PFMEAs using the new methodology. The difficulty implementing PFMEAs with the new method using Excel increases geometrically with the number of product components and the complexity of the process.

AIAG Position Change on Handbook FMEA Method Compatibility with Excel

The original draft of the AIAG VDA FMEA Handbook put out for stakeholder review stated in bolded print:

“When products and processes are complex it is recommended that specialized software be used to apply the FMEA method”.

Despite no changes being made to the FMEA method contained within the released handbook to make it compatible with Excel, the recommendation for using specialized software for complex products and processes was removed. Over that past year, the AIAG has been attempting to roll back the lack of Excel compatibility statement in the handbook draft. Scot Grey, AIAG Project Manager for the AIAG VDA FMEA Handbook stated the following in an AIAG webinar prior to the release of the handbook:

“So we want to be clear here that we have tested, validated with suppliers, that the methodology can be executed with either spreadsheets, again typically excel, or specialized FMEA software.”

Despite AIAG’s changed position, a simple fact remains. The new FMEA methodology contained within the released handbook is an adoption of the VDA FMEA methodology. The VDA FMEA methodology was designed to be implemented with specialized VDA FMEA software. The new FMEA methodology is not designed to be implemented with Excel.

Detailed Description of New PFMEA Method Compatibility Issues with Excel

There are four issues that will be faced by companies who attempt to use Excel to implement the new PFMEA methodology using Excel. They are:

- required inclusion of information not currently required by the AIAG 4th Edition PFMEA methodology and not required to assess the risk of the manufacturing process;

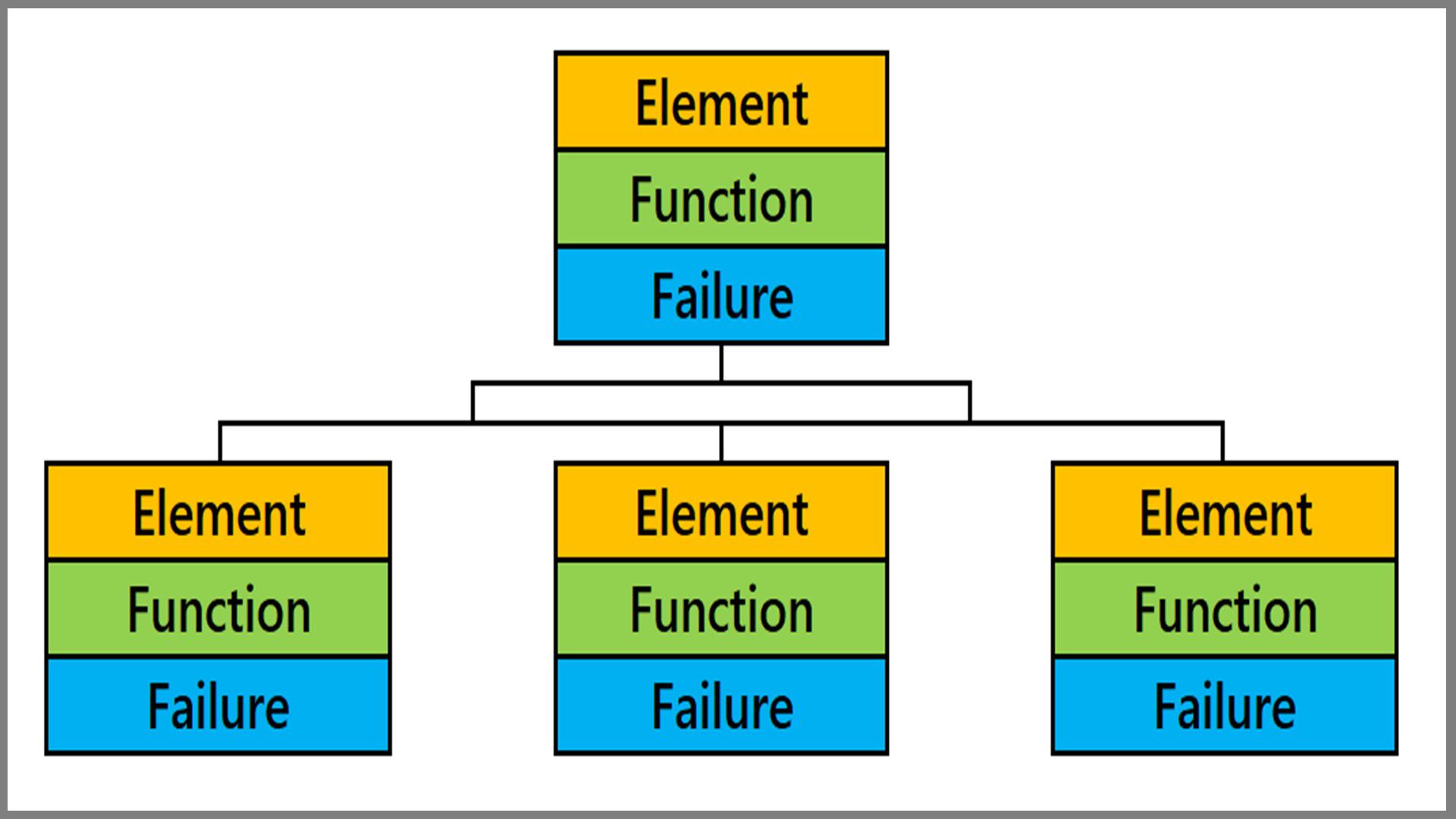

- need to determine whether to use a sort order for the spreadsheet to support the creation of the AIAG VDA Structure, Function and Failure trees or the PFMEA since both are contained in the same spreadsheet;

- increased difficulty in interpreting the PFMEA due to the additional information and sort order;

- need to maintain linkages between multiple DFMEA and PFMEA spreadsheets.

To learn more about what makes up a good Process (and Design!) FMEA, check out the webinars below: