Usage Risk Management Module Overview

When designing a product, it is important to consider the impact of the user of the product on the product’s performance. It is possible to correctly define the Customer Requirements, properly translate the Customer Requirements to Design Requirements, create Product Design Specifications that define a product that will meet the Design Requirements and build a product which is compliant with the Product Design Specifications only to have it fail when the user uses the product in manner that was not designed for. The goal of the Quality Plus® Usage Risk Management Module is to help a company manage risk due to failure of a properly designed and manufactured product because of the way it was used.

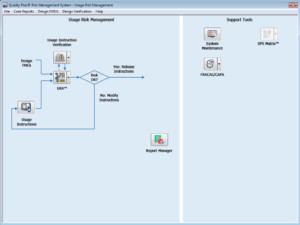

The Quality Plus® Usage Risk Management Module guides the design engineer through a structured decomposition of the use of the product and enables the design engineer to capture critical information of what the user may or may not do that can cause product failure. This information is placed in a custom Product Usage Model for current use as well as a Master Product Usage Model for future use for products of similar type.

Using the Usage Risk Assessment Methodology developed by Harpco® Systems, information from the custom Product Usage Model is used to autogenerate a Usage Risk Assessment (URA™) and supporting Usage Verification Plan. After modifying the Occurrence Ratings of the URA™ with information gained from performance of the Usage Verification Plan, the designer uses the URA™ output in combination with risk-based thinking to prioritize which design failures caused by usage patterns that must be worked on to achieve the greatest product risk/benefit ratio.

The Usage Risk Management Module is dynamically linked to the FRACAS/CAPA Module.

I have been working with Harpco Systems for 20 yrs and have seen how their products and services continue to improve to meet customer demands. Finding a disciplined approach to relate field performance to product design specifications is rare. There just is no uncomplicated way to do this correctly. Harpco’s approach handles all the complication internal to their software so the engineers can focus on other aspects of their job. Because the known failure mechanisms and causes are mapped, this information can be used for problem solving and driving continuous improvement in manufacturing.

Harpco Systems provides some of the most technologically advanced FMEA software tools on the market……. Harpco Systems has become known as the Modern FMEA for a reason. Its structured, simplified and sustainable.

“We used Q Plus to achieve Q1 and ISO 16949 successfully at the Ford Motor Co. Monroe BAO Plant. The software promoted linked documentation that prevented issues at internal and external audits. Assured the quality documents at the operations production level had all relevant and concurrent information that was reviewed in the program files. QPlus allowed the program members to create a baseline “Hot End Exhaust” database that produced linked documentation from the DFMEA to the production visual aids the operators used to perform correctly.”