Requirements Risk Management Overview

If your company designs products, properly defining Customer Requirements and translating them to Design Requirements design engineers can design to are two of the greatest sources of risk your company faces. When errors are made in defining Customer and Design Requirements, more fortunate companies uncover  them during the design process and experience large product development financial losses and/or extended delays in design release. Less fortunate companies don’t learn of their mistake until the product is in the marketplace and suffer far larger losses and delays.

them during the design process and experience large product development financial losses and/or extended delays in design release. Less fortunate companies don’t learn of their mistake until the product is in the marketplace and suffer far larger losses and delays.

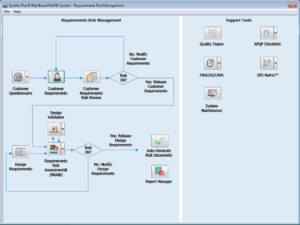

The bad news is in most cases there is no such thing as risk free Customer and Design Requirements. It is very common for customers to present you with requirements that are competing, conflicting and/or beyond the limits of available technology. The Quality Plus® Requirements Risk Management Module is designed to show you how to define risk optimized Customer and Design Requirements to provide you and your customer with product designs that have risk/benefit ratios you both will be happy with.

Using the Requirements Risk Assessment® (RRA®) methodology developed by Harpco® Systems will show you how to use “risk-based thinking” and avoid taking on jobs your company lacks the necessary resources to handle. For opportunities that represent a good match for your company, you will learn how to provide your design department with clear directions so they can create the appropriate design and a strong design validation strategy for assessing the design’s adequacy in meeting the Customer Requirements before release.

The Requirements Risk Management module will also help you manage the impacts of changes to Customer and/or Design Requirements on both the design department and manufacturing processes. Potential impacts of changing Customer and/or Design Requirements can be known in minutes.

Finally, if you are unfortunate and experience product failures in the field after a design is in production, the Quality Plus® RIPS® (Rapid Integrated Problem Solving) technology will integrate information from the Requirements Risk Management Module with information gained during the use of the Design Risk Management, Usage Risk Management and Manufacturing Process Risk Management Modules to help guide you to a rapid resolution of the issue.

I have been working with Harpco Systems for 20 yrs and have seen how their products and services continue to improve to meet customer demands. Finding a disciplined approach to relate field performance to product design specifications is rare. There just is no uncomplicated way to do this correctly. Harpco’s approach handles all the complication internal to their software so the engineers can focus on other aspects of their job. Because the known failure mechanisms and causes are mapped, this information can be used for problem solving and driving continuous improvement in manufacturing.

Harpco Systems provides some of the most technologically advanced FMEA software tools on the market……. Harpco Systems has become known as the Modern FMEA for a reason. Its structured, simplified and sustainable.

“We used Q Plus to achieve Q1 and ISO 16949 successfully at the Ford Motor Co. Monroe BAO Plant. The software promoted linked documentation that prevented issues at internal and external audits. Assured the quality documents at the operations production level had all relevant and concurrent information that was reviewed in the program files. QPlus allowed the program members to create a baseline “Hot End Exhaust” database that produced linked documentation from the DFMEA to the production visual aids the operators used to perform correctly.”